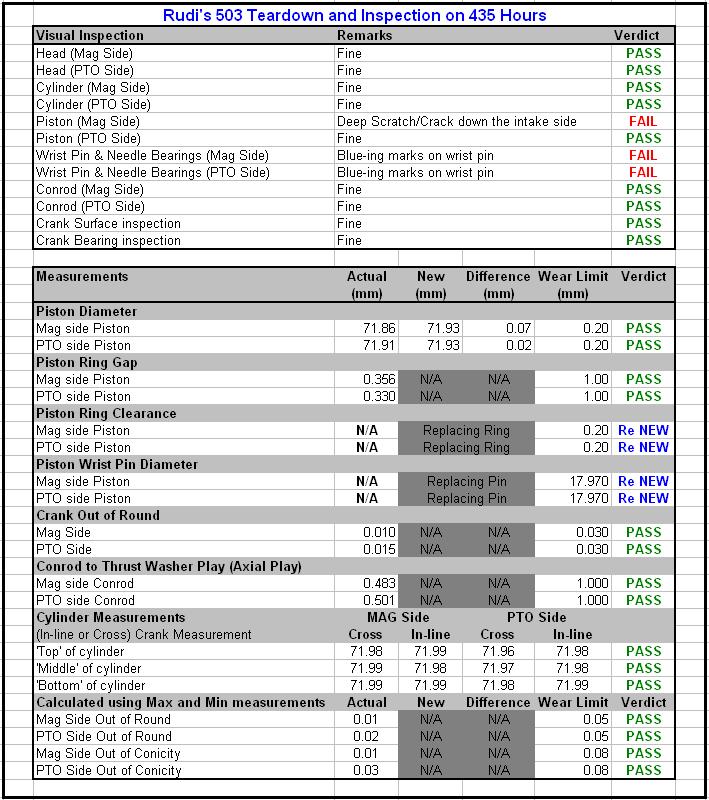

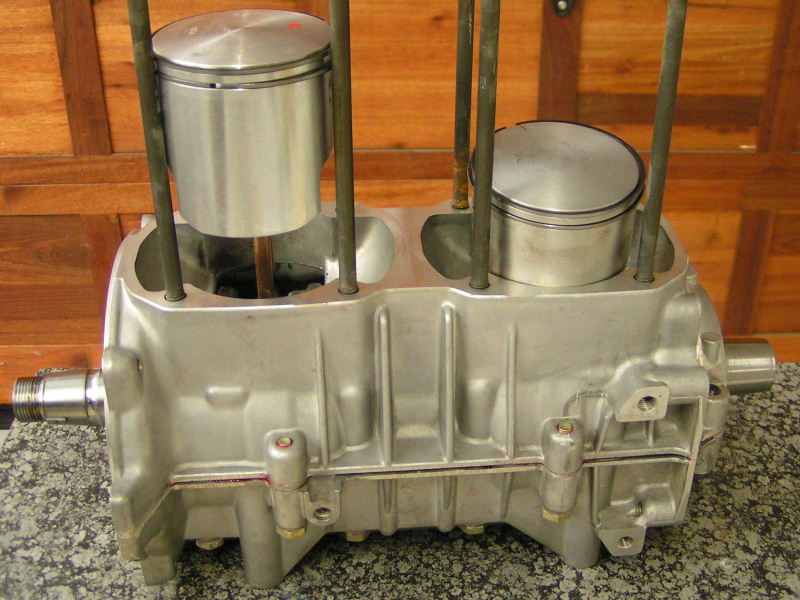

Well I decided to open up my Rotax 503 and inspect it, and thought it good to document the process and provide some photos for the guys that haven’t done it before.

My motor has 435 Hours on it and it has never skipped a beat. It always starts after priming on the first or second flick of the prop by hand. Some say I’m Crazy to open up a perfectly good running motor and that these little 503 motors are bullet proof and can easily do a 1000 Hours!

Well here are my reasons: My motor is 7 years old and I’m starting to see that some of the rubbers showing their age. The first owner did very little hours in the first 2 years of the motors life, so it sat around with infrequent flying perfect to get corrosion. In addition it has never been opened and inspected before. I initially wanted to sell the plane, but I made a decision to keep the plane for another 3 years. Rotax recommends an overhaul on 300hours or 5 years what ever comes first. So adding all these factors together I decided to open up and check it out.

PART 1:

======

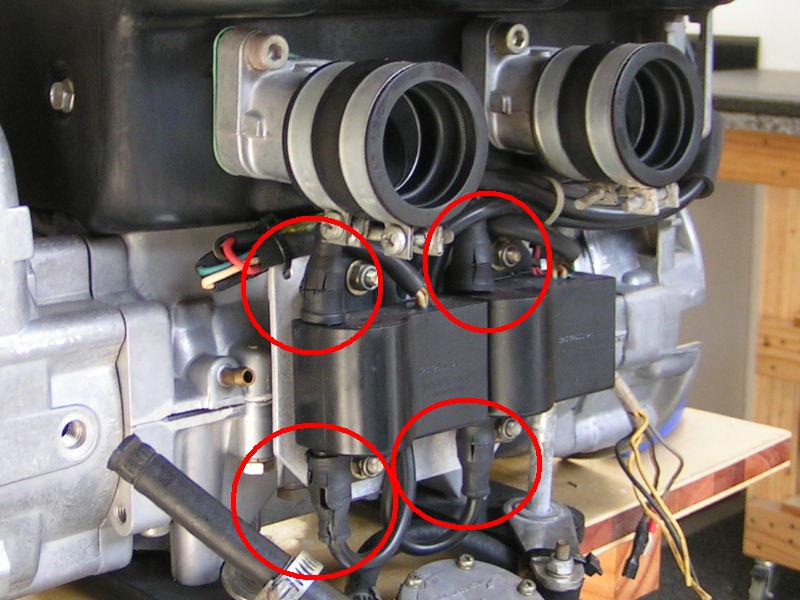

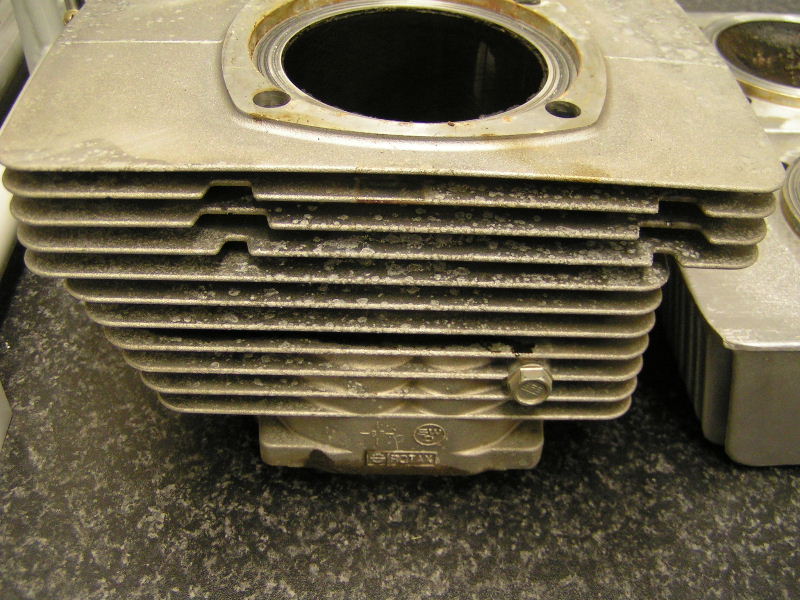

I borrowed the flying schools bearing and flywheel puller and started to strip the motor. The first thing I noticed after I pulled the cowls is the amount of corrosion that formed on the cowl and heads. Keeping in mind that my plane was always hangered except on the occasional fly-away. During those fly-aways I can only remember it standing in the rain under its cover once or twice. In addition I can only remember flying in the rain once or twice as well. The corrosion wasn’t visible on the outside on the motor, and it was kind of a shock to me because I typically keep my motor very clean. Now I can imagine what motors look like standing outside, or even at the coast!

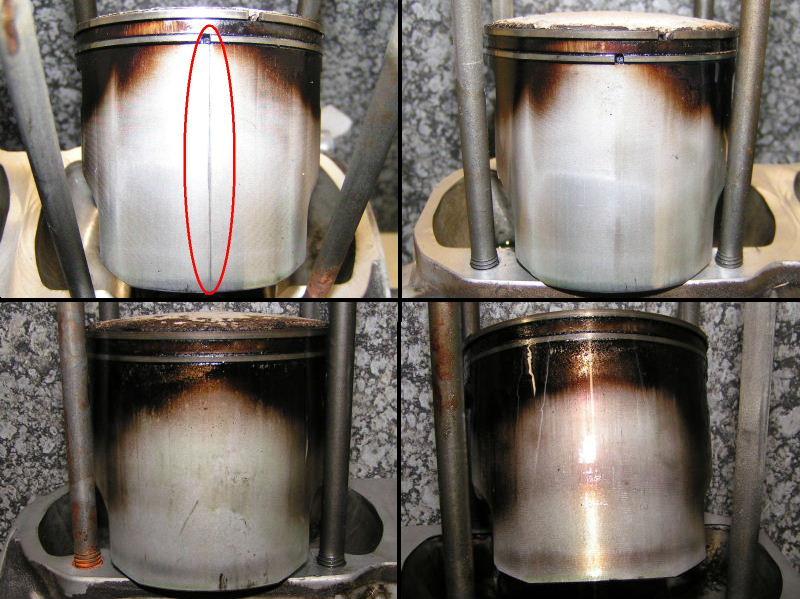

The next picture shows close-ups of the heads and piston tops. A fair amount of carbon formed burning a nice muddy brown. The camera flash makes it look lighter than it is. The experts tell me this is a sign of good burning motor, the jetting is just right.

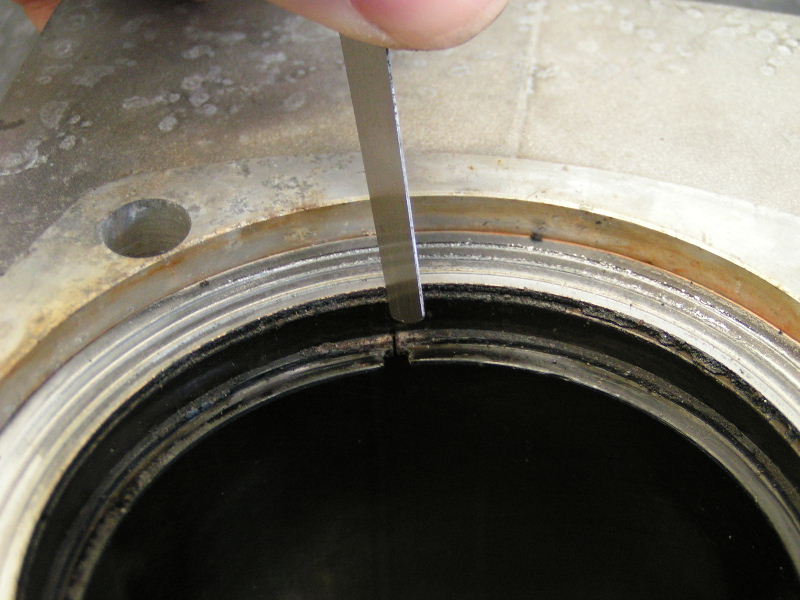

Next I inspected the rings. Both the top rings were nice and loose, but both bottom rings was stuck on 50% of the diameter of the piston side.

Then I noticed potential problem #1. The magneto side piston had a slight score line right down the centre in the middle of the intake manifold side. It is almost as if something very small went down the intake manifold and scored the side of the piston. It is just visible and one can hardly feel it, but it is there. I checked the cylinder walls and there is no scuffing. What ever small this was it did nut hurt the walls. Below is the intake manifold side view of pistons is on top with the corresponding exhaust side below.

Next I turned the motor upside down and removed the circlips from the piston wrist pin. You can see where you insert a pick to remove the circlip shown on the table.

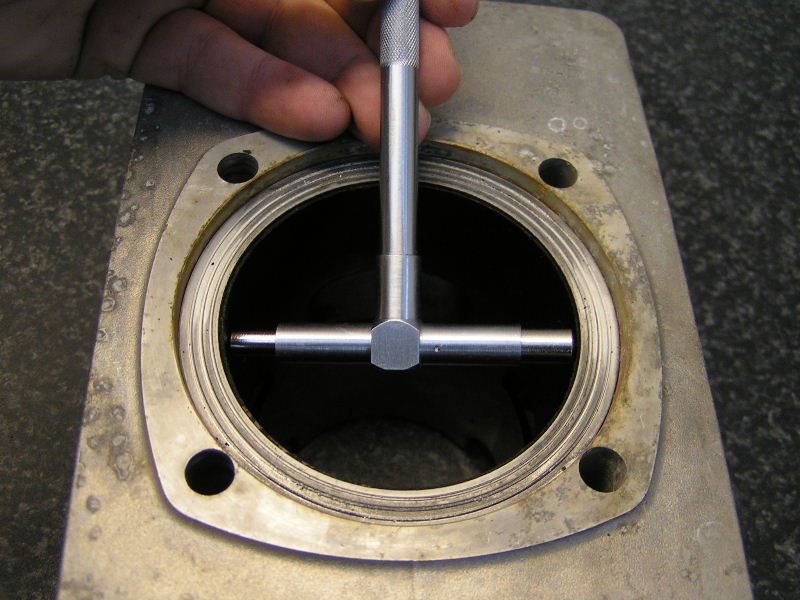

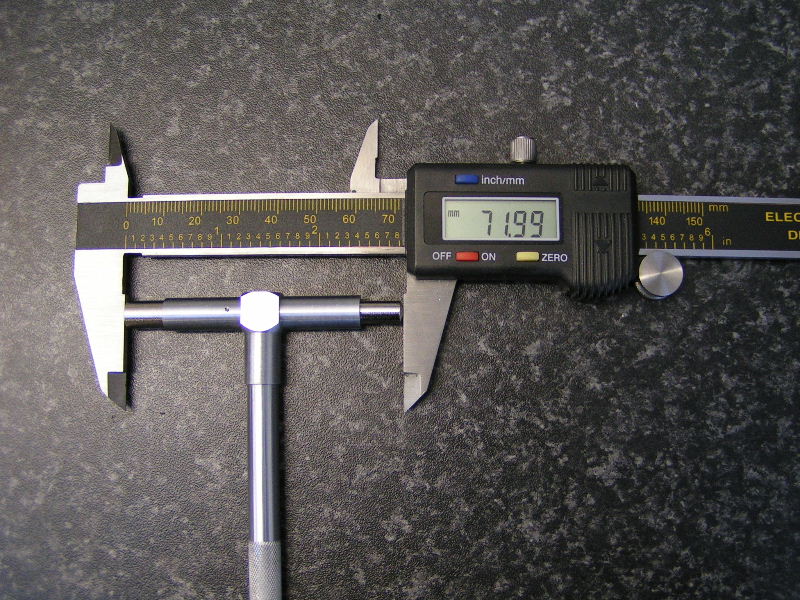

Next I pondered a while how to best remove the wrist pins, since I do not have a wrist pin puller…and then Eureka I got an idea that worked very well. I used 2 deep sockets and a big clamp. The small socket is smaller than the wrist pin and pushed it out into the bigger socket. I used 12mm and 19mm deep sockets and the wrist pin slid out without putting a lot of force on the clamp. Very easy, but pictures speak a thousand words. See below:

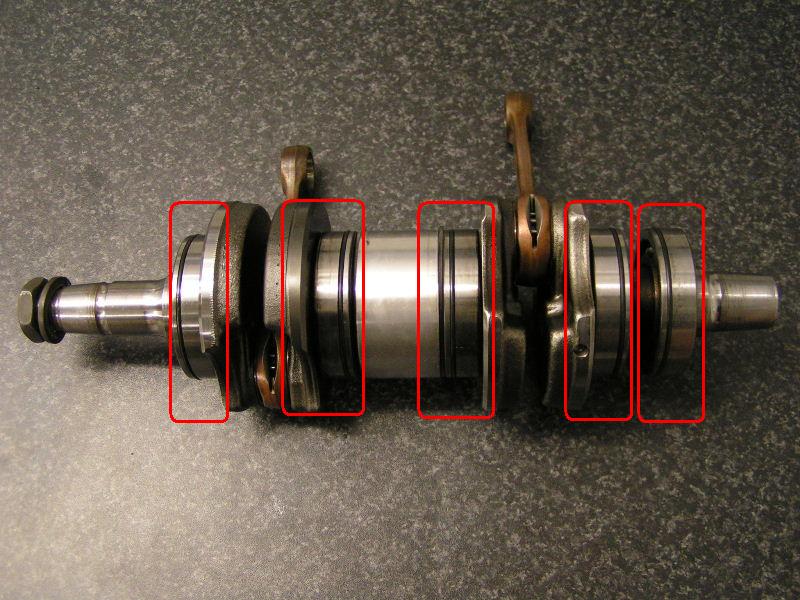

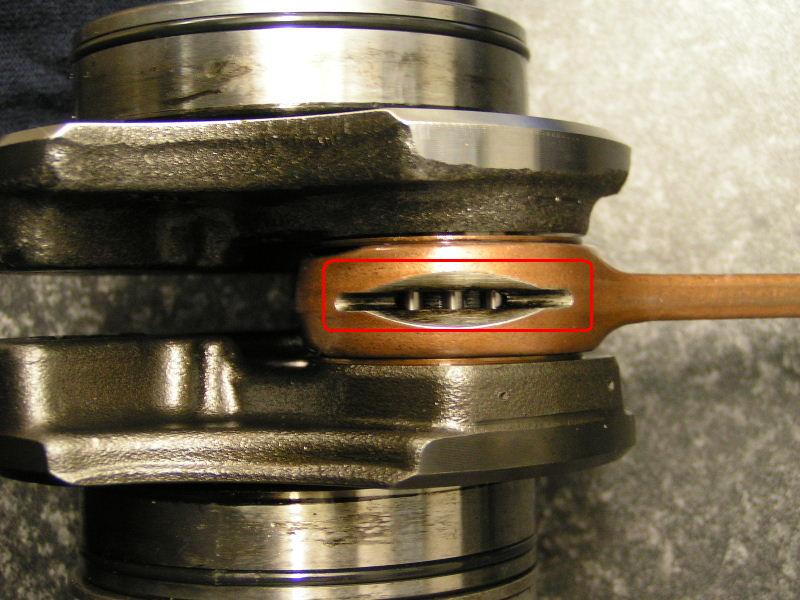

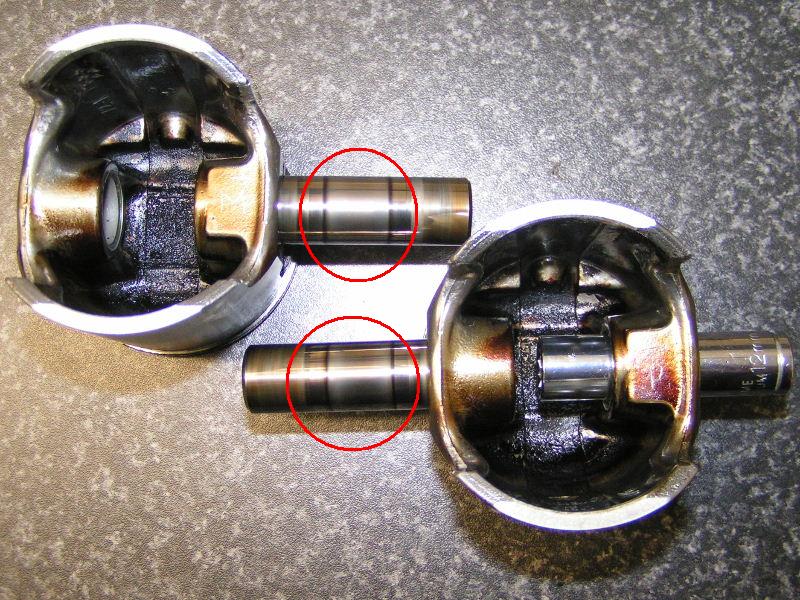

After removing all 31 needle pin bearings and the 2 rings I noticed problem #2 on the motor. Notice the 2 rings on the wrist pins. If you look at it closely you can see it is “blue-ingâ€Â, the ring is dark blue in colour which means the metal got hot and ‘burned’. It was evident on both wrist pins and occurred exactly where the needle pin bearings run as the pictures below depict. This means that some time during the motor’s life that the wrist pins did not get enough lubrication and hence the metal got hot and ‘burned’. Anybody got any ideas on why and when this happens???

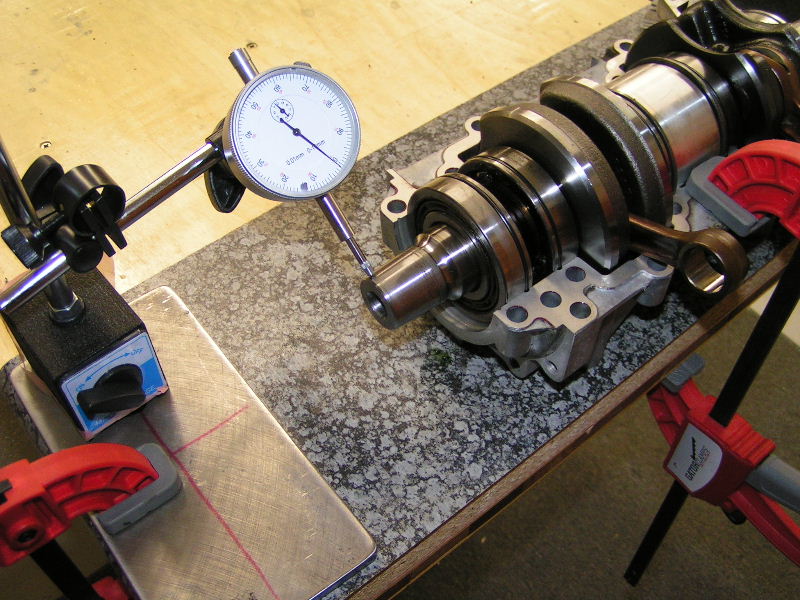

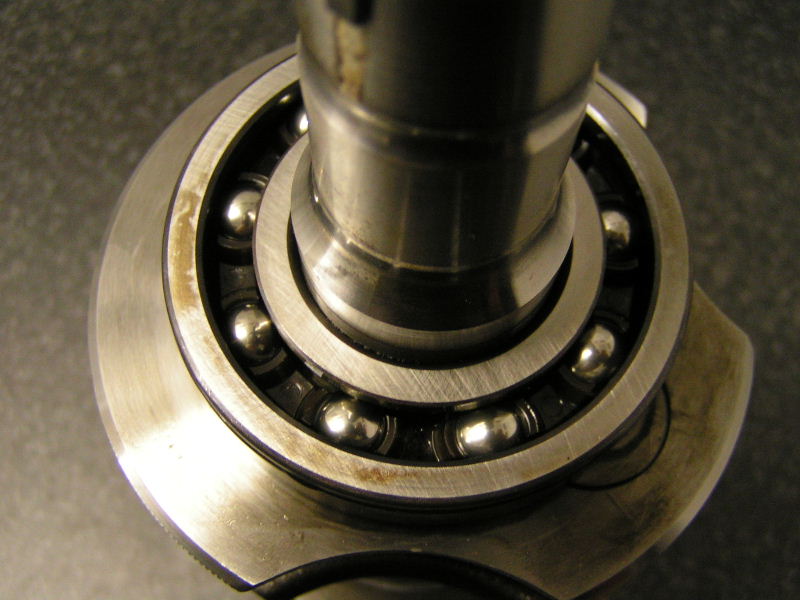

Well I still need to open up the crank case and inspect the crank and measure up the pistons, cylinders and crank, but will do that in the next week or so. If you guys are interested I will take pictures of the whole process and post it here...Let me know?

Any case I need to take my pistons and wrist pin to the experts to inspect and see what they say about the 2 potential problems I have found so far. In the mean time you guys can speculate in the forum below and tell me what you think the verdict will be. Your comments appreciated.

Kind Regards

Rudi